Bobbin residue cutter Custom Order Product

The process of winding and unwinding the bobbin in the dyeing process of the yarn is a necessary process, and cutting the remaining yarn in the bobbin to remove it is a process that can only be done by a person because it is difficult to automate.

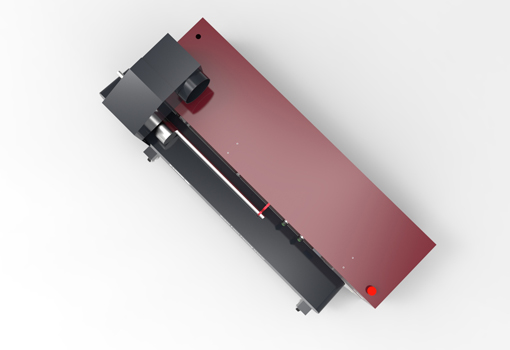

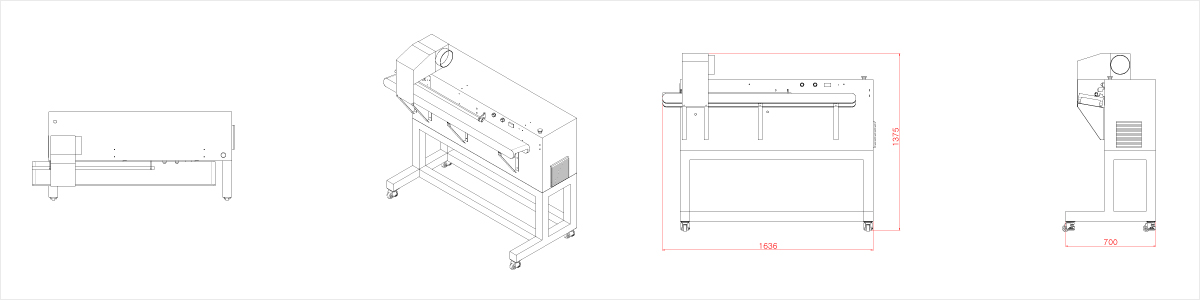

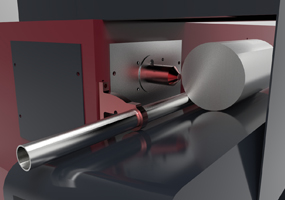

Developed by ELASER, the bobbin residue cutter is a device that allows the laser to be used to cut the residue and reuse the bobbin regardless of the amount of residue left. One person can do the work of the existing 10 people and the water spraying device for fire prevention is built in, so you do not have to do additional work just by placing the bobbin on the conveyor of the equipment.

The type of residues can be cut regardless of the material and thickness, and the bobbins must have a metallic shape.

ELASER's technology does not damage the bobbin and does not damage the bobbin at all. Depending on the laser power, there are two options: one-time machining and multiple machining.

Video

Features of equipment

-

Economical CO2 laser application

DC type CO2 laser is equipped to maximize the cost ratio which enables economical and efficient operation

-

Mounting conveyor device

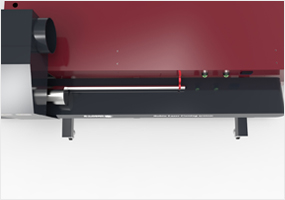

It is equipped with a conveyor device that automatically feeds the bobbin to the laser machining position

-

Mounting safety devices

A safety device was installed to prevent the light path from being damaged. When the human body is exposed on the laser light path for the safety of the operator, an emergency stop device is installed

-

Fast and easy to work with

Simply putting the bobbin on the conveyor is very fast because all the work is done, and it also has the effect of reducing labor costs.