Laser Cleaner Custom Order Product

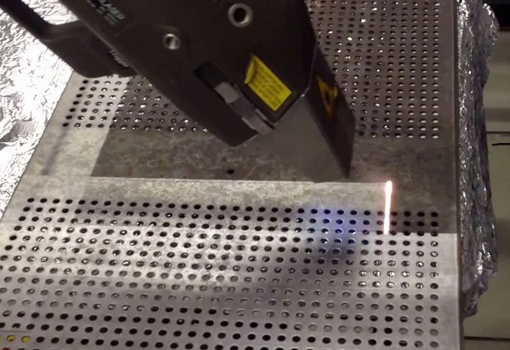

It is equipment that irradiates to the surface of metal using 1064nm wavelength laser to clean. It is widely used equipment for processing metal surfaces such as molds and ships.

The laser can be used from 100W to over 1KW, and the cleaning width, speed, laser pulse and frequency can be changed by applying high performance galvanometer. It also provides a tool to keep the target, laser head and focus.

All of our products can be customized according to your needs and work environment.Specification

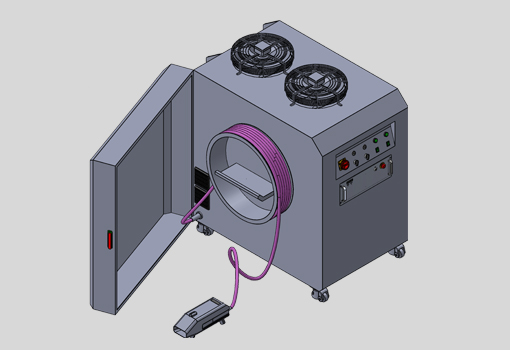

- Main BodyPotable & Manual operation

- Cooling method

air-cooling type (basic), water-cooled type at

500W or more - Laser output100W ~ 1KW or more

- laser wavelength1064 nm

- Scan widthMax 150mm

- Maximum focus lengthMax 180mm

- Laser deliveryOptic fiber less than 3m

- SoftwareSelf-developed system controller

- PowerAC 220V single phase

Function

- Fiber Laser application

1064nm fiber laser, optimized for metal surface

processing - High performance galvanometer

High beam performance with high performance

galvanometer - Ease of operationEasy to work with mobile design

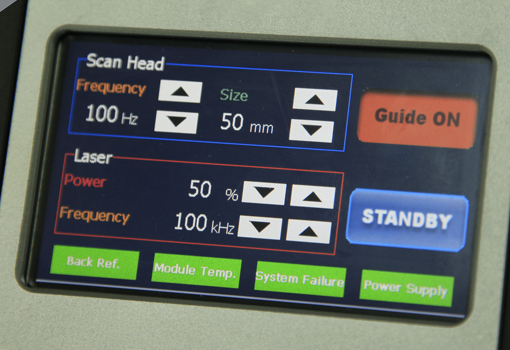

- Easy control operationPanel configuration for maximum ease of operation

- Focus maintenance toolProvides continuous focus maintenance tool

- Various laser output selection

100W ~ 1KW laser output selectable

- Customizing possibility

equipment modification according to user's

requirement (automation equipment) - 1 year WarrantyProvided Our standard warranty period.

- Operation Knowhow

Educational specialist conducts tailored training

for your clients

Video

Features of equipment

-

Fiber Laser apply

Optimized for metal surface processing by applying fiber laser of 1064nm wavelength. In addition, various outputs can be selected from 100W to 1KW or more.

-

High-performance galvanometer application

High-performance galvanometer is applied to ensure uniform transmission of laser beam and quality reproducibility in the machining area.

-

Easy control operation

The operation panel is configured to control only the necessary functions such as laser output, frequency, machining area setting, and scan speed.

-

Ease of movement

It consists of moving wheel + gun type Maximize ease of movement and operation.