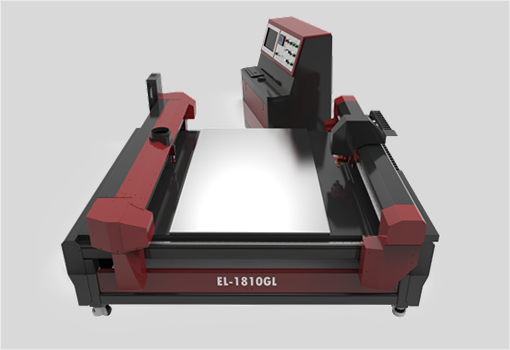

EL-1810GL Laser+CNC

The EL-1810 GL is a special device designed specifically for laser and CNC machining in one bed.

It has wide processing area (1800x1000) corresponding to super 3 * 6 size and it is convenient to work with honeycomb table (laser) vacuum plate workbench (CNC) as a base. High-performance AC Servo motor is adopted as the base, and high precision ball screw drive system is applied to maximize work stability and machining speed. The integrated control tower maximizes user convenience and guarantees durability by bed heat treatment and precision machining process.

The CNC spindle can be applied variously according to the work material and working speed, and the laser can select various oscillators (150W ~ 250W).

All of our products can be customized according to your needs and work environment.Specification

- Machining range1800 x 1000mm

- Maximum machining speed

60000mm/s

- Laser typeCO2 Laser DC glass tube / RF metal type selection

- Laser outputDC TYPE : 80W~180W / RF : 30W~250W Selection

- Spindle type5.5Kw / 6000~18000rpm / Air-cooled

- ColletER-25

- CAM programE-Laser Cut 8.0 / Made in Korea CNC CAM Program

- Data input methodUSB Interface direct connection, USB Memory, PCI

- Data command languageG code, HPGL, Internal language only

- Supported computer operating system

Windows XP through Windows10

- Drive systemServo + Ballscrew system

- Transfer methodscrew Transfer method

- Power supply3-phase 380V 60Hz

Function

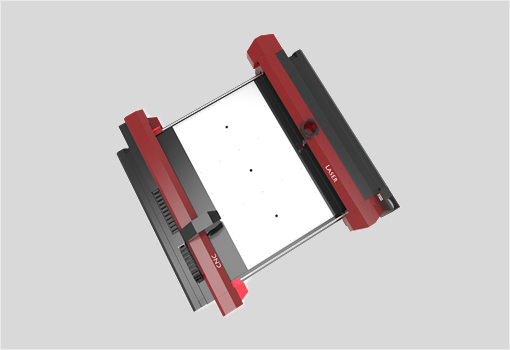

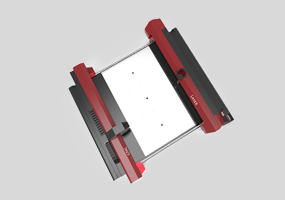

- Twin gantry structure

Two gantry structures to prevent interference and

contamination between each operation - Precision motor

applicationHigh quality precision AC servo motor

- Control tower applicationControl of laser and CNC in control tower

- Multi language support

Controller Multi language support such as English,

Japanese, German, Chinese - CNC domestic controller

Applied to domestic controller, convenient and

precise control possible - Convenient Laser

Focus alignmentQuick and easy focus alignment with focus tool

- W.A.B.E. Laser optics

Technology to produce high quality beams

with patented optical technology - Ballscrew conveying

systemDurable ball screw system provides stable

machining quality - Wide range of lasers available

Various types of lasers

- Various spindles available

Various spindles can be selected according to the

work characteristics - Customizable

Modification of equipment according to user's

requirement - One year warrantyOur standard warranty period.

- Operational Knowhow Education

Experts Conduct Customized Training for Your

Customers

Video

Features of equipment

-

Twin gantry structure

Two gantry structures, each equipped with a gantry laser and spindle, allowing them to work without interference and contamination.

-

Integrated Control Tower

An integrated control tower that controls the laser and CNC has been added to make it easier for the operator to switch between jobs.

-

High precision ball screw is used

Precision machined ball screws minimize misalignment and minimize overload displacement errors.

-

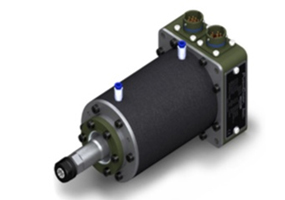

AC Servo Motor Application

Precision machining is possible by using high quality precision motors.

Option

-

Variable spindle applicable

You can select spindles that match the characteristics of the job by torque, RPM, and output.

-

Various types of lasers can be applied

The basic type DC type glass tube laser is applied to construct economical equipment and various lasers based on CO2 laser can be applied if necessary.

-

Vision CCD Contour cutting

It is a device that can recognize the image through Outline mark by applying CCD camera and perform cutting work.

Optionally selectable. -

W.A.B.E. Apply technology

Patented laser optics technology applied.

Significantly reduces beam size to ensure precise machining.

It can be selected as an option.

Material processing samples

-

Fabric and Leather

-

Glass

-

Metal

-

Wood and Natural Materials

-

Stone

-

Paper

-

Plastic