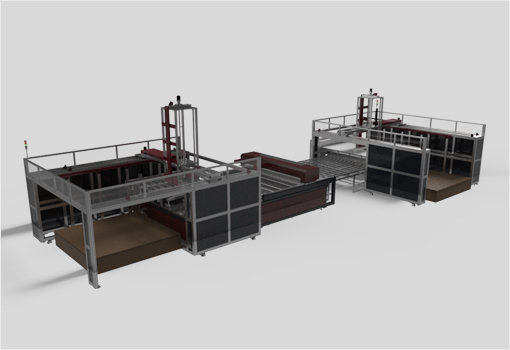

ABS Laser Cutting System FA system

ABS material, which is mainly used as ceiling finish for bathroom ceilings and interior finishes, has been cut and bent by hand without automation process, resulting in a lot of manpower and defect rate.

We have developed a laser cutting system that can automate this. By automating the loading, cutting, bending and stacking of processed products, we have increased human efficiency and minimized the defect rate.

The ABS laser cutting has to be carried out without a hitch, applying a higher power CO2 laser than 250W, and the process is designed to operate without error with PLC linked control.

Specification

1. Product loading part

- Equipment size3000 x 6000mm

- Maximum loading size

3000 x 6000mm

- Control systemPLC program control

- Main drive systemPneumatic cylinder and motor drive

- part function Loading of processing material automation line

3. Conveyor Transport Part

- Equipment size3000 x 6000mm

- Conveyor length1st: 2000mm / 2nd: 2000mm / 3rd: 2000mm

- Main drive systemMotor drive belt system

- Control systemPLC program control

- Part functionAutomatic transfer between each process

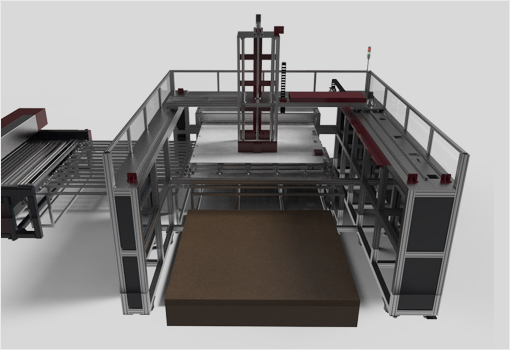

2. Laser cutting part

- Equipment size3000 x 6000mm

- Machining area3000 x 6000mm

- Laser250W CO2 laser RF type

- Drive systemrack&pinion + servo motor system

- Control systemLaser controller + PLC program

4. Bending Part

- Equipment size3000 x 6000mm

- Maximum bending size

3000mm

- Control systemPLC program and thermal sensor control

- Main drive systemPneumatic cylinder and motor drive

- Part functionBending of a specific part

Video

Features of equipment

-

Full process automation

Automated specialties allow 24 hours operation by placing processing materials without the need for personnel.

-

RF type 250W CO2 laser application

High cutting power of 250W or more is applied to cut cutting and cutting time as sharp as knife. RF type laser is applied considering laser life and beam quality.

-

Laser control + PLC program

Each process execution and inter-process connection control are programmed based on the PLC and the laser part is processed by applying a dedicated controller

-

Maximization of work efficiency

Since the work is completed by simply placing the material on the system, it is possible to increase the efficiency of the on-site work by reducing the loss of manpower and speeding up the work.