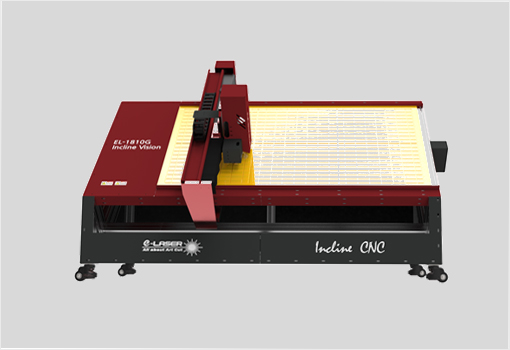

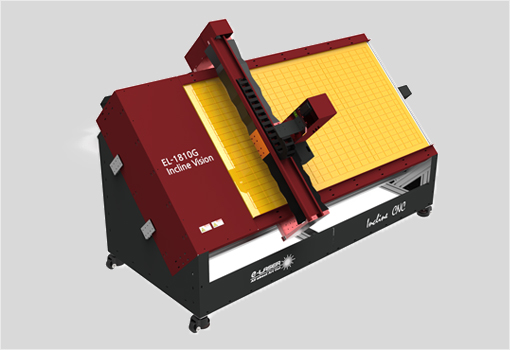

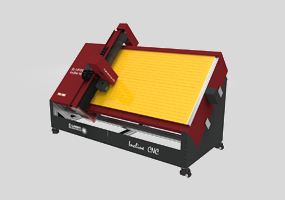

Incline CNC

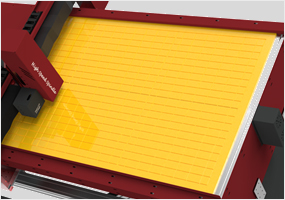

It is a CNC equipment that can be used effectively in a small space. Work table is tilted by 45°, and space of more than 500mm can be secured than existing equipment.

It is easy to use for beginners by applying very easy to use software. Machine Vision can be installed and optimized for sign production.

By applying the design to enhance the rigidity of equipment and so on, it is the equipment that can get the desired processing quality even if the customer wants to work continuously.

All of our products can be customized according to your needs and work environment.Specification

- Machining area1800x1000x75mm(z)

- Table typevVacuum table for T-slot

- Power supply

AC 380V 3P 60Hz

- Maximum number of revolutions

~ 56000rpm

- Spindle capacity1.1KW~6KW

- Drive typeDirect high frequency spindle

- ColletER16 (Max 10)

- Transport motorServo motor

- Transport speedMax 12m/min

- Transport DeviceBall Screw, LM Guide

- Repeatability0.005mm

- Accuracy of movement0.01mm

- ControllerUniversal CNC Controller

Function

- Optimize space utilization

45 ° tilted to optimize space utilization

- Gentry type structure

Gentry type structure for convenient working

environment - T-slot bed applicationConvenient and variety clamping environment

- High precision ball screw application

High precision ball screw is used for more accurate

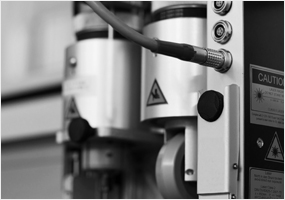

machining quality - High output spindle

High frequency inverter enables high speed

rotation of tens of thousands of RPM - Ease of equipment

mobilityRollers are installed, making it easy to move

equipment as needed - Apply Universal Controller

Various control such as absolute origin, block skip,

precedent control, etc. - Customizable

Customized development of various jigs and

special spindle applications - One year warrantyOur standard warranty period.

Features of equipment

-

Optimize space utilization

Leverages the equipment by 45 degrees, ensuring more than 500mm of space compared to the existing equipment, so that it can be used in a narrow working space

-

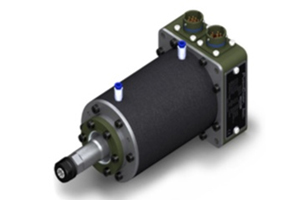

High precision servo motor application

Precision machining is possible by using high-quality precision motors

-

High precision ball screw application

Use a high precision ball screw.

Precision machined ball screws minimize misalignment and minimize overload displacement errors. -

Domestic controller applied

By applying the CNC multi-axis controller of Korea, stability of control and localized software are added to the convenience of work.

Option

-

Variable spindle applicable

You can select spindles that match the characteristics of the job by torque, RPM, and output.

-

T-slot or Vacuum bed selection

A T-slot bed is used as a base and an optional vacuum clamping bed can be selected.

-

Can be equipped with Vision CCD

The Vision CCD can be used for registration cutting. Can be optimized for sign production.

-

Custom production possible (special function)

To fulfill the functions required by the customer for special purposes such as Machine Vision Device configuration is possible.

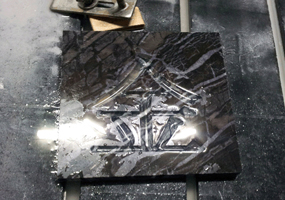

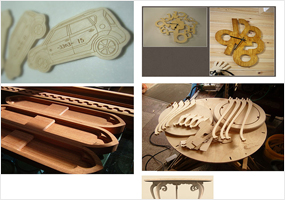

Material processing samples

-

Stone

-

Plastic

-

Metal

-

Wood and Natural Materials