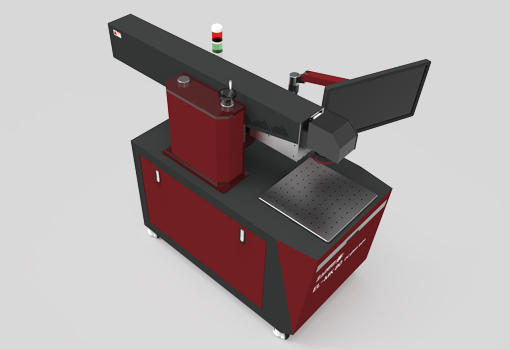

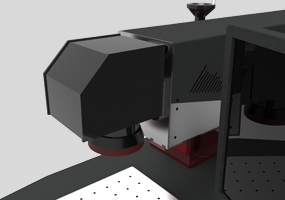

EL-MKDC Series Glass tube

With the increasing demand for laser marking, we are constantly evolving to meet the needs of our customers. CO2 laser is applied, it is possible to mark quickly and precisely on non-metallic material by applying high-precision scanner, and it is composed of convenient device for various work such as auto focus guide beam, smokestack and jig table.

E-laser has accumulated vast amount of data through many experiences and experiments, so you can get the processing quality that meets the customer's needs in any material response of customers.

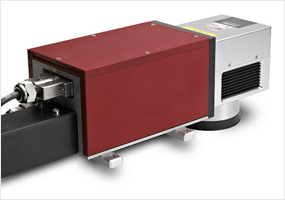

The laser oscillator can be selected from CO2 laser 30W ~ 80W depending on the working purpose.

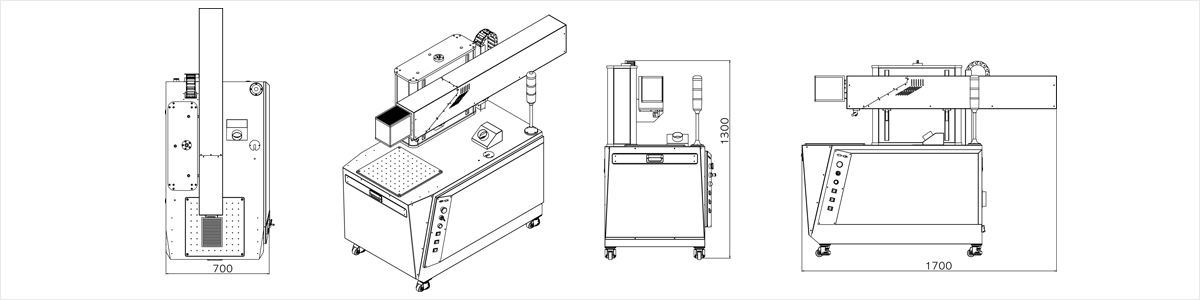

All of our products can be customized according to your needs and work environment.Specification

- Machining area70 X 70 mm ~ 180 X 180mm (default)

- Laser typeCO2 Laser DC type Glass tube

- Laser wavelength10.6nm

- Laser output30W ~ 80W (Default)

- Repeatability3㎛~5㎛

- Cooling MethodWater Cooling (Default)

- Supported computer Operating system

Windows XP or later Windows10

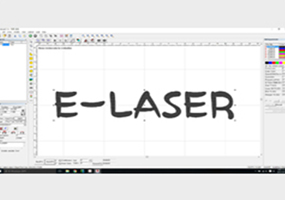

- CAM programMarking mate or EZCAD (Default)

- Max marking speed2500 mm / s (default)

- Input voltage AC 220V Single phase 50 ~ 60Hz

- Power Consumption600W ~ 2KW

Function

- Ease of movement of equipment

Light and small, easy to move

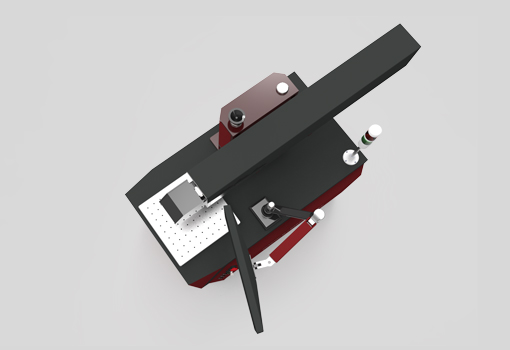

- Precision Scanner Application

Excellent quality due to high quality scanner

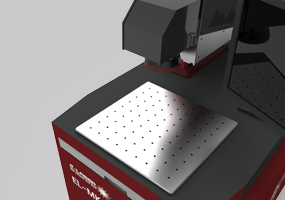

- Multi-purpose table

Various jig can be installed,

making it convenient for work - Multi language support

Support for multiple languages such as English,

Japanese, German, Chinese - Convenient Focus alignment

Quick and easy focus alignment with focus beam

- Using various lasers

Structural design that can use various kinds of

laser source - Customization possible

Equipment modification according to user's

demand (automation equipment) - One year warrantyOur standard warranty period.

- Operational Know-how training

Professional training tailored to your needs

Video

Features of equipment

-

Glass tube CO2 laser application

Equipped with economical glass tube type laser, it has high caustic ratio.

-

Application of multi-purpose Jig Table

If you need a jig depending on the workpiece, we provide aluminum work table for easy mounting and processing.

-

High precision scanner application

Using a precision galvanometer-applied scanner, it achieves fast and accurate quality.

The know-how of using various kinds of scanner lens makes it possible to respond perfectly to each material. -

Convenient software application

It supports both vector and bitmap files and supports most image files.

We have put various functions in easy to use and provide instruction manuals and training.

Supports up to windows 10.

Option

-

Various customizing possible

It can be customized to meet your needs with various marking machine characteristics.

Special production jig and special laser applicable. -

Variety of lasers available

Various lasers based on CO2 Laser can be applied.

10.6nm, 9.3nm, etc. can be selected and applied to various wavelength lasers. -

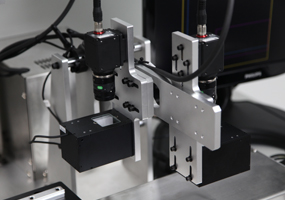

Machine Vision applicable

The most basic positioning and alignment functions as well as various machine vision functions can be realized by combining laser control technology.

-

Automated design possible

It can be designed to be applied to various automation lines by combination of laser and scanner.

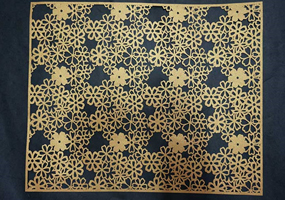

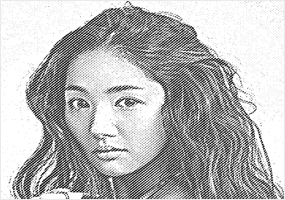

Material processing samples

-

Fabric and Leather

-

Glass

-

Metal

-

Wood and Natural Materials

-

Paper

-

Plastic

-

metal marking

-

metal marking