3D marking series

With the increasing demand for laser marking, E-laser's marking machines are constantly evolving to meet customer needs.

It is a marking system that can perform general marking, stepping machining, and 3-dimensional machining on various materials such as plastic, ITO, metal by using fiber laser pulse laser and marking head using dynamic beam expander.

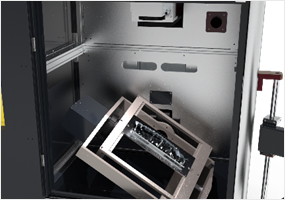

The 3D marking machine consists of various parts such as a tilt-index stage for adjusting the rotation angle of the product, a suction assembly for removing the residue after laser machining, a PC auto focus guide beam for equipment control, a smoke ejector, and a rotary jig table.

E-laser is able to produce the best results for any customer's requirement based on vast amount of data with many experiences and experiments.

All of our products can be customized according to your needs and work environment.Specification

- Machining range300*300

- Laser typeFiber Laser

- Laser wavelength1064 nm

- Laser output10~100W

- Repeatability± 25 ㎛

- Cooling systemAir-cooled (basic)

- Supported computer Operating system

Windows XP through Windows10

- CAM programController based on MM3D

- Max marking speed2500 mm/s

- Input voltageAC 220V

- Power consumption600~2Kw

Speacial Feature

-

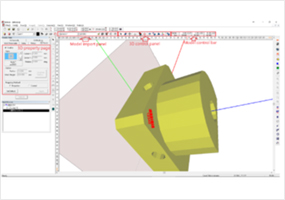

Application of MM3D Controller

STL 3D model support / 2D graphic rendering / MM3D controller for marking irregular surface

-

Fast and accurate Scan head

Highly accurate and dynamically scanned heads that are mechanically and electrically compatible provide fast marking

-

Dynamic Focusing

The Scanner is driven by a high-performance linear motor, enabling very fast and precise 3D machining.

-

Mounting of rotary shaft handle

Constructs a handle with two rotating shafts and rotates according to the marking position of the material surface to perform stereoscopic marking