EL-1390LKM

The EL-1390LKM is a special machine that can process both metallic and non-metallic specially designed by our company.

It has a wide machining area (1300x900) to meet customer's needs.

Advanced features and convenience features have been combined.

It is a metal / non-metal equipment that can mark and cut non-metallic material, marking and cutting of metallic material, which is equipped with advanced functions and convenience functions such as autofocus, convenient beam control and laser output digital meter.

It adopts the patented W.A.B.E technology of E-laser (Option) and has ACS (Anti Corrosion System) structure. You can protect the equipment even in rough work.

Cutting Gas Quick Change System makes it easy to switch between metal and non-metal.

The laser oscillator can be selected from 150W to 400W CO2 laser depending on the working purpose.

Specification

- Machining area1300 X 900 mm

- Maximum machining speed

60000mm/min

- Resolution0.025mm

- Repeatability0.01mm

- CAM programE-Laser Cut 8.0

- Data input method USB interface direct connection, USB memory

- Supported computer

Operating systemWindows XP or later Windows10

- Maximum cutting thickness

SUS: Up to 1.0T, MS: Up to 1.2T,

Acrylic: 30T (150W standard) - Character processing Minimum size

English:1.5mm x 1.5mm /

Korean, Chinese:3.5mm x 3.5mm - LaserCO2 Laser: Use RF type or DC type 150W or more

- Data InstructionContents Dedicated language

- Power supply

Single phase 220V 60Hz 2200W (domestic type)

or more - Drive systemServo motor+Ballscrew system

Function

- Safety cover

Acrylic cover for hazard prevention during

processing - Precision motorHigh quality step or servo motor application

- LCD Display

Convenient environment by changing job setting

and saving data - Multi language support

Support for multiple languages such as English,

Japanese, German, Chinese - Auto Focus Alignment

Laser head recognizes the distance from the workpiece

and focus alignment (during metal working) - ACS SystemAnti Corrosion System for pvc and pomax

- Red beam guideLaser beam visualization with red beam guide

- Application of flame detection sensor (option)

Application of sensor to cut off laser when flame

occurs during processing - Application of W.A.B.E technology (option)

Applying technology to produce high-quality beam

with patented optical technology - Application of special

laser headApplication of special optical head

- Various lasers available RF(150~400W) / DC(150W~260W)

- Customizable

Remodeling and configuring of equipment

according to user's requirement - Warranty for 1 year Our standard warranty period

Video

Features of equipment

-

Apply safety cover

By attaching a safety cover to the front of the machining area, you can safely check the progress of the work.

-

High precision ball screw application

Use a high precision ball screw.

Precision machined ball screws minimize misalignment and overload displacement errors. -

AC Servo Motor

Precision machining is possible by using high quality precision motors.

-

Special laser head

Our laser head was designed by us.

It is a completely sealed laser head considering laser optical characteristics.

Option

-

W.A.B.E. Apply technology

Patented laser optics technology applied.

Significantly reduces beam size to ensure precise machining.

It can be selected as an option. -

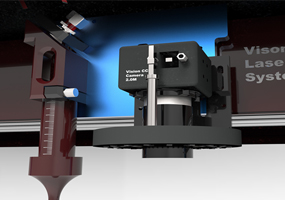

Vision CCD Contour cutting

It is a device that can recognize the image through Outline mark by applying CCD camera and perform cutting work.

Optionally selectable. -

Select Work Table

Provides a basic aluminum blade.

Various tables according to customer's demand

1. Vacuum table

2. Honeycomb table

3. Aluminum blade

4. Acrylic honeycomb table. -

Selectable RF type CO2 Laser

Basically DC type glass tube is applied to CO2 laser.

RF type laser according to customer's demand.

It can be selected according to the laser output. 30W ~ 400W can be selected.

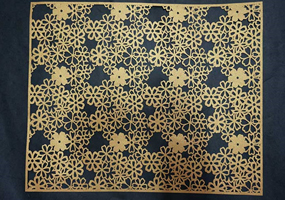

Material processing samples

-

Fabric and Leather

-

Glass

-

Metal

-

Wood and Natural Materials

-

Paper

-

Plastic

-

metal marking

-

metal marking